Msw Processing Plant

In today’s rapidly urbanizing world, effective waste management is not a choice-it’s a necessity. Our Municipal Solid Waste (MSW) Processing Plant is a modern, environmentally conscious facility designed to handle the complexities of urban waste through a combination of mechanical, biological, and thermal technologies. We don’t just manage waste-we turn it into a resource.

What We Do

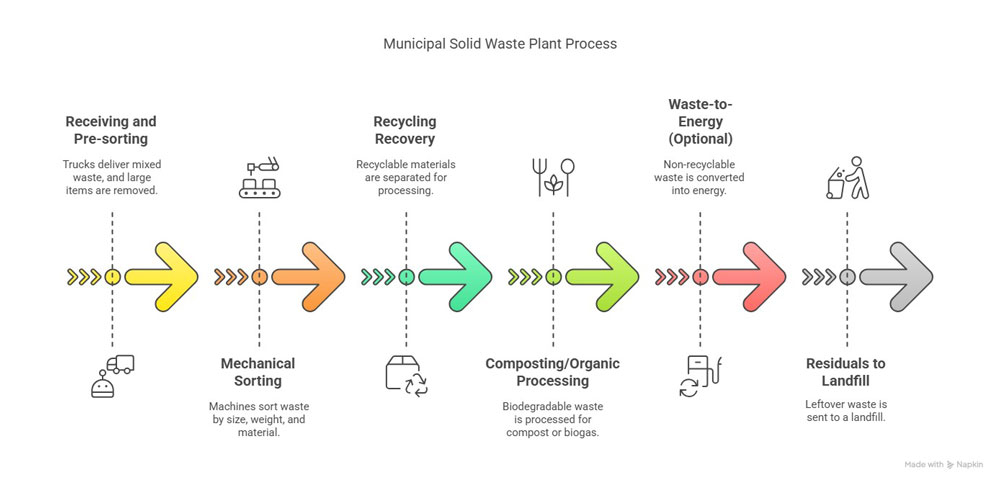

Our MSW processing plant provides a comprehensive, end-to-end solution for urban solid waste. The process begins with waste collection and ends with resource recovery, energy generation, and safe disposal of inerts. We integrate smart waste management practices with sustainability principles, supporting the circular economy.

Core Processing Units

1. Waste Reception & Pre-Sorting

Incoming MSW is weighed, documented, and inspected before being sent to the tipping floor. Here, large and hazardous items are manually removed to ensure operational safety.

2. Mechanical Segregation

- Trommel Screens: Used to separate biodegradable waste from recyclables and inerts based on size.

- Magnetic Separators: Extract ferrous metals.

- Eddy Current Separators: Recover non-ferrous metals.

- Air Classifiers: Distinguish light materials (plastics, paper) from heavier inerts.

3. Biodegradable Waste Management

- Composting Units: Aerobic composting of organic matter to produce nutrient-rich compost.

- Bio-Methanation: Anaerobic digestion generates biogas and organic slurry, which can be converted into energy or liquid fertilizer.

4. Dry Waste Recovery & Processing

- Recyclables: Separated materials such as PET, HDPE, paper, and metals are compacted and sent to authorized recyclers.

- Refuse Derived Fuel (RDF): Non-recyclable but combustible fractions are shredded and densified for use as alternative fuel in industries like cement manufacturing.

5. Sanitary Landfilling

Residual and inert waste is disposed of in scientifically engineered landfills with proper liners, leachate collection systems, and gas management infrastructure.

Technological Highlights

- Automation & IoT Integration: Real-time data monitoring, predictive maintenance, and operational efficiency through SCADA systems.

- Energy Efficiency: Minimal energy usage per ton of waste processed, with on-site energy generation using biogas and solar panels.

- Emission Control: High-efficiency particulate air (HEPA) filters, biofilters, and misting systems reduce odor and air pollution.

- Water Recycling: Leachate and process water are treated and reused, minimizing freshwater use.

Environmental Impact

- Up to 90% diversion from landfill

- Reduction of over 30% GHG emissions per ton of waste

- Generation of clean energy from waste (biogas, RDF)

- Support for afforestation through compost distribution

Social & Economic Contributions

- Employment Generation: Skilled and semi-skilled jobs for local communities.

- Livelihood Opportunities: Integration of informal waste pickers into formal systems with fair wages and protective gear.

- CSR & Community Programs: Educational tours, awareness drives, and local compost giveaways.

Compliance & Certifications

- Fully compliant with Solid Waste Management Rules, 2016 (India)

- ISO 9001:2015 | ISO 14001:2015 | ISO 45001:2018 certified

- Environment Clearance from State Pollution Control Board and CPCB

- Third-party audits and real-time public reporting

Sustainability Goals

Our MSW plant contributes directly to:

- Swachh Bharat Mission & Smart Cities Initiative

- Net-Zero Waste Strategy and Circular Economy Roadmap

Let’s Build a Cleaner Future Together

We invite municipalities, industries, NGOs, and community stakeholders to collaborate with us in creating a zero-waste future. Whether you are looking for end-to-end waste management solutions, consulting services, or CSR partnerships, we’re here to help you make a lasting impact.