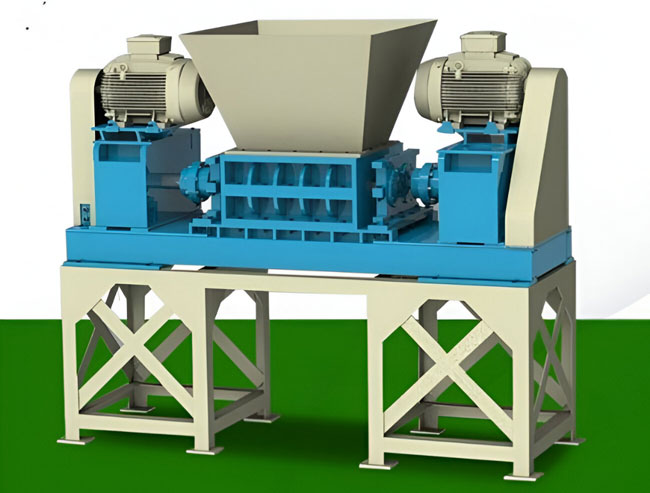

Shredder Machines

Key Features & Benefits:

Optimized for Waste Reduction

Reduce waste volume by up to 80%, cutting down on storage space, transport costs, and landfill contribution. Perfect for preparing materials for compacting, baling, or recycling.

Multi-Material Shredding Capability

Capable of shredding paper, plastic, PET bottles, aluminum cans, light steel, textiles, wood offcuts, and mixed solid waste. Customizable blade options available for specific material types.

High Capacity for Continuous Operation

Engineered for non-stop use in demanding environments. Handles up to 500 kg/hour of mixed materials with minimal downtime. Optional conveyor feeding and auto-reverse for jam prevention.

Eco-Friendly Waste Processing

Supports sustainable waste management by enabling efficient material separation and pre-processing for recycling. Designed for integration with balers, separators, or granulators.

Built to Withstand Industrial Use

Heavy-duty steel frame, hardened cutting shafts, and reinforced motor for long-term durability, even in the harshest conditions. Corrosion-resistant and low-maintenance design.

Applications:

- Recycling Facilities

- Solid Waste Processing Plants

- Municipal Waste Management

- E-Waste Disposal

- Packaging Waste Reduction

- Industrial Manufacturing Waste Streams

Our shredder machine is more than just a tool—it’s a waste management solution that helps you improve efficiency, meet environmental goals, and ensure long-term cost savings.

Types of Shredder Machines We Offer:

| Type | Motor Power | Rotor Diameter/Speed | Shredding Chamber Size | Capacity | Application |

|---|---|---|---|---|---|

| Single Shaft Shredder | 15–150 kW | 300–800 mm | 600×800 mm to 2000×2500 mm | 300–5000 kg/hr | Plastics, wood, textiles, rubber, light metals |

| Double Shaft Shredder | 30–250 kW | 10–50 RPM | 800×1000 mm to 3000×2500 mm | 500–20000 kg/hr | E-waste, metal scraps, bulky industrial waste, municipal solid waste |